By Trey Fly

Air quality in educational facilities has always been very important. Schools have a high concentration of people that come and go every day, often bringing in new germs from the outside world. There are many studies over the years that correlate poor air quality with lower test scores and increased absences. It is all hard to quantify with so many variables, but not many experts would argue that air quality does not matter.

The thing is, air quality has been largely taken for granted by those directly involved in the industry. Prior to this year, people did not typically worry about the air they were going to breathe in a certain space, even though humans consume exponentially more air per day than they consume in food or water. Air filtration in general has always been “behind the scenes.”

Fast forward to 2020 and the era of COVID-19. Suddenly, air quality and air filtration are top of mind for the entire world. A quick Google search or simply flipping through the TV channels will almost certainly land you on a news story about COVID and the implications of people breathing in highly occupied spaces. People are not only scared of the virus, but they are now acutely aware of pathogens that can be spread through the air.

Educational facilities should be safe places for both students and staff members, not only in a physical sense, but also in relation to the air being provided for those occupants to breathe. It should be the facility’s obligation to create a safe learning space for the people within their buildings.

Below are some suggestions for improving indoor air quality in educational facilities. These will vary in ease of conversion and price. A suggestion would be to assess the systems currently being used in your facility and see if there are upgrades that make sense and could be financially sustainable. It is my intent to provide you with realistic suggestions that could be implemented quickly and without too much financial burden.

- Make sure your filters fit properly.

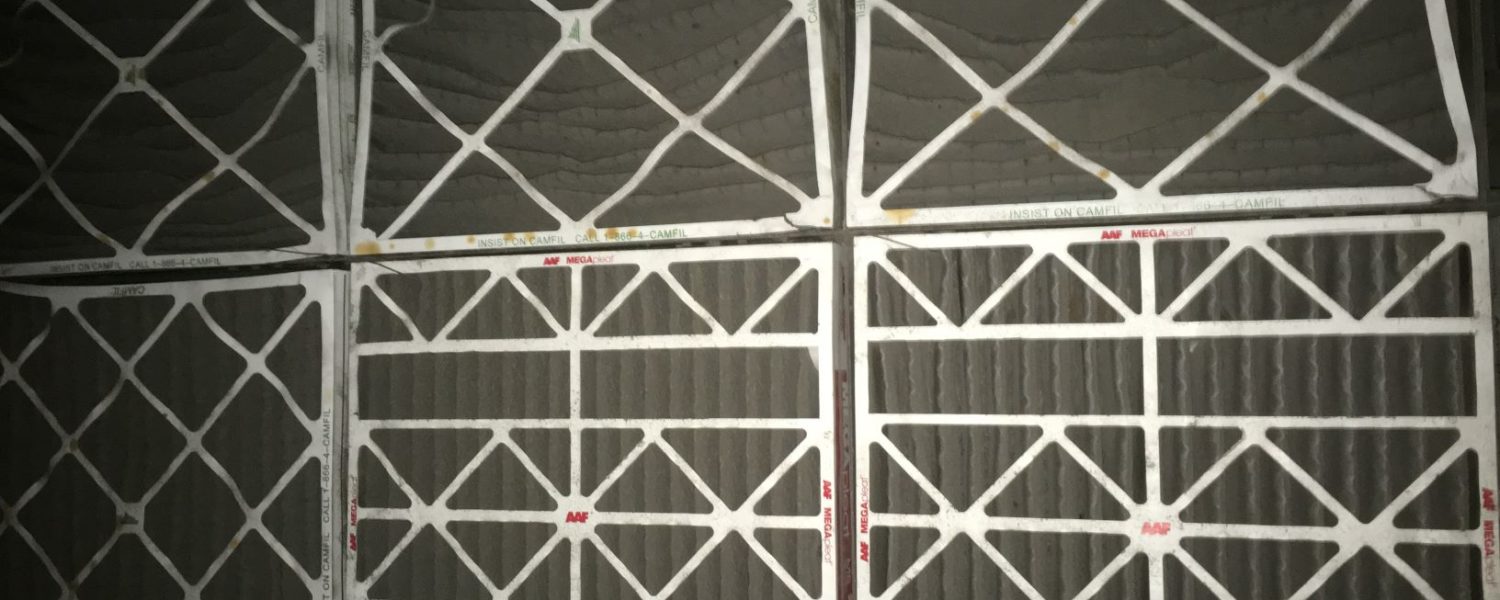

This is an easy, zero-cost improvement that can be made immediately. Filters will only catch what goes through them, so if there are gaps between your filters, we call that “air bypass.” This is essentially unfiltered air.

Please make sure your filters can do their job, and to do that, the air must travel through them. For this analysis, survey your air handling equipment and make sure filters are the right size and fit tightly. You can add spacers, gasket, or tape between filters if there is air bypass.

- Change your filters on time when they need to be changed.

There is no need to change them too often and you do not want to wait too long. Changing filters too often is simply a waste of money. That is easy to understand. On the other hand, leaving filters in too long can create a whole slew of problems, most of which can contribute to poor indoor air quality. Filters left in too long can blow through, meaning they may have fit tightly at one point, but because dust has built up on them, there is added resistance that can compromise the integrity of the filter (which leads to air bypass).

Another problem with leaving filters in too long is microbial growth – mostly mold and bacteria. Air handlers provide an optimal place for microbial growth, and it is best to avoid turning your filters into petri dishes full of pathogens that can get airborne.

Finally, leaving filters in too long can decrease your air handler’s efficiency and ultimately lead to higher energy bills.

- Upgrade your filters.

For reference, “filter efficiency” refers to the amount and size particles that a filter is designed to capture. A higher efficiency filter means that it will catch more particles and smaller particles. I am not going to tell you the exact efficiency you should be using, because there are too many variables and every facility is different. But what I will tell you to do is find out what efficiency you are using and see what the other options may be.

Having a filter expert will not only give you options but will also tell you the real-world implications of the changes that you are making. A filter with a higher efficiency will capture more particles, but it may also restrict the air, which could negatively impact the performance of your air handler. We want to be realistic with these upgrades and make sure you know the long-term financial considerations of your selection.

- For your air handlers to be optimized, clean your evaporator coils and make sure your drain pans stay clean.

Since coils are typically downstream of the filters, adding a better filter will only do you so much good if you have a dirty coil. We recommend cleaning coils to get the unit as close to optimal as possible and then protecting the coil with filters that fit properly.

Ultraviolet lights should be considered if your budget will allow for it. These are designed to shine on the coil and will keep the coil free of all pathogens, biofilm, and mold for as long as you maintain the bulbs. An optional low-cost measure would be to add some drain pan treatment to prevent sludge or microbial growth from accumulating in the drain pan. This build up can lead to unwanted leaks and poor indoor air quality.

I would like to make one additional note about HEPA (high efficiency particulate air) filters, since they are such a key word right now. HEPA filters are the best at removing viruses and small pathogens from the airstream; however, adding HEPAs to typical commercial HVAC systems is pricey and requires major retrofits. If you want the absolute best filtration and money is not a concern, then investigate HEPAs.

There are many factors involved in indoor air quality, and by doing the best you can within your means, you will be improving the indoor air quality in your educational facility and protecting those most valuable assets inside – the people.

Trey Fly is a past president of the National Air Filtration Association, www.nafahq.org. He is a third-generation owner of Joe W. Fly Co., a 54-year-old air filter distributor and service provider, www.joeflyco.com.